Using digital helpers in a targeted manner

Dürr Consulting supports companies on their way to a Smart Factory

How can companies use digital tools to save time and money and improve the quality of their products? To that end, Dürr Consulting performs digital readiness assessments at customer locations from various industries, makes recommendations for action and accompanies initial implementations. The following example shows which measurable advantages customers gain as a result.

At a medium-sized manufacturer of power tools, Dürr Consulting first gave an overview of the use of digital products in production. The experts from the Dürr Group provided information on where digital products can be utilized and what potential can be leveraged by them.

As a second step, they took a close look at the company’s process structures along the entire value chain, including areas such as purchasing, assembly, sales and logistics.

“But we do not just leave it at theoretical data,” states Cornelius von Podewils of Dürr Consulting. He and some colleagues spent half a day observing the production. In this way, they gained an impression of the conditions on site.

Roadmap for the next years

On the basis of the insights gained, Dürr Consulting developed recommendations for action and coordinated the roadmap for the next four years with the company. An important role in prioritization is always played by questions such as “When will the return on investment be reached?”, “How can product quality be improved?” or “How much transparency does the customer want in his factory?” For some companies, it is enough to make sure faults are reported or employee ergonomics are improved. Therefore, it is not necessary for the entire process to be digitally mapped.

Dürr Consulting did not stop at generating a concept for the tool manufacturer, but also accompanied it for six months during the implementation of the initial measures. This included internal training courses where employees were provided with basic knowledge of digital products. The training content included, for example, the scope of digital applications, implementability in existing IT infrastructures and technical feasibility.

Creating acceptance in the workforce

Consultant Cornelius von Podewils is convinced that “without the appropriate background, these tools are used to a lesser extent and employees make no suggestions for improvement.” The training courses also cleared an important hurdle: “The employees recognize the advantages and see the digital products as support and not as competition.”

As a further measure, the consistency of digital data was improved. Often different file formats are used in one process, which makes it difficult for different departments to evaluate and interact. The digital consistency of the database lays the foundation for making data uniformly available.

Under the heading of “production program optimization,” physical processes such as warehousing were improved. “Thus, we have not only considerably reduced the capital tied up in inventories, but also optimized production processes. By utilizing digital products, we have been able to increase the optimization percentage,” reports Cornelius von Podewils. In this context, the philosophy of Dürr Consulting is: Only when the physical processes have been exhausted will digitalization be performed.

Running plants at optimum capacity

In addition, the tool manufacturer’s Manufacturing Execution System (MES) has been expanded in such a way as to interconnect all machines and systems within it. “This is the prerequisite for achieving optimum utilization of all plants,” says the expert from Dürr Consulting. This also allows planning of maintenance and service intervals.

Supporting this medium-sized company on its way to becoming a Smart Factory is not an isolated case for Dürr Consulting. Many customers come from the mechanical engineering sector, but also from the transportation industry, agriculture and agribusiness, and the automotive industry.

Dürr Consulting also benefits from the expertise of Dürr Digital Factory in its digitalization projects. Their software experts evaluate feasibility and technical implementation possibilities.

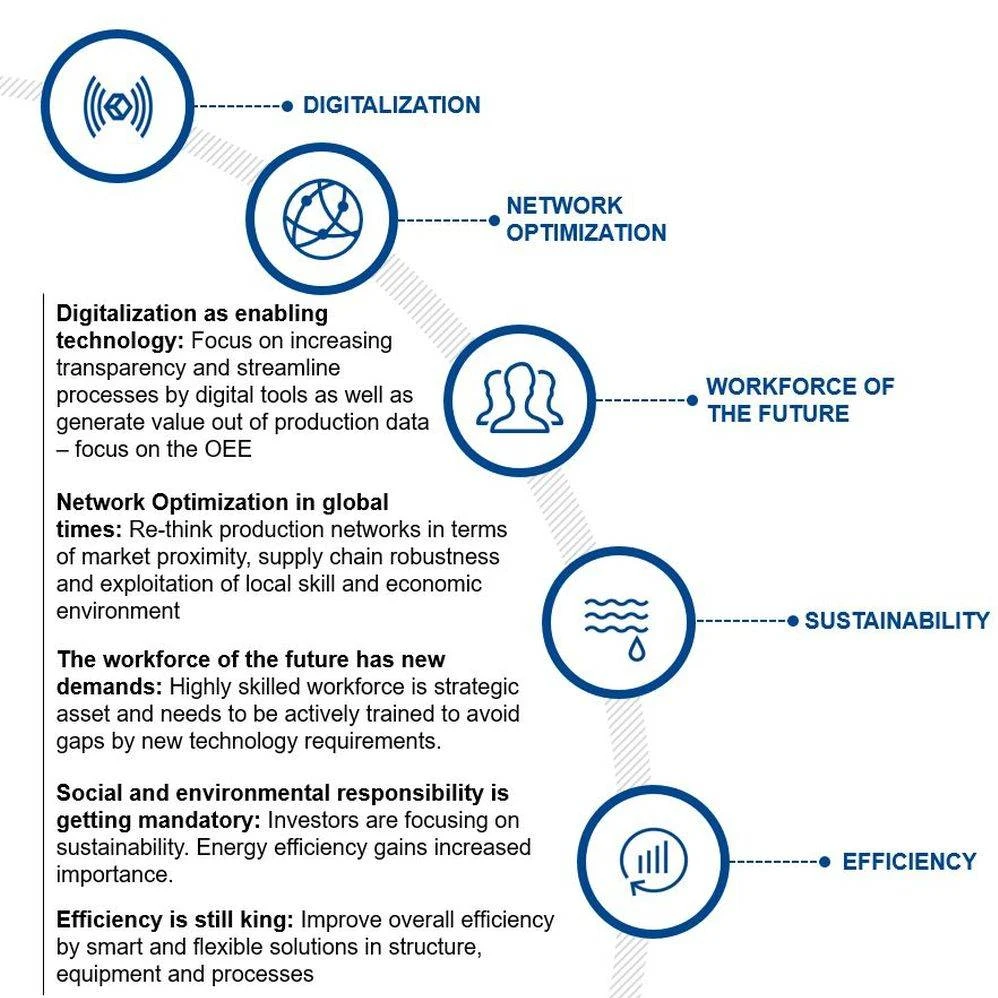

The focus on these subjects

Get to know more about this topic and download the trend study of Dürr Consulting.

Do you want to adapt your company and your industrial production to the global digitalization? You want to learn about the key technologies in the manufacturing industry and know how to react to the challenges and trends in the digital IT infrastructure? You would like to bring a digital twin to life and use augmented reality in the value creation of a factory? We look at all these questions and a few more in our study "Managing global digitization in industrial production".

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany