Assembly planning

Challenges for manufacturing companies

In today's fast-paced environment, manufacturing companies face significant challenges, which are particularly noticeable in the assembly process. Increasing cost pressure due to intense global competition is forcing companies, especially those in high-wage countries, to constantly increase their productivity. In addition, there is an increasing product variance and fluctuating quantities, which require a high degree of flexibility and adaptability. These dynamics demand efficient and at the same time flexible assembly systems. To achieve this, innovative and customized solutions must be developed for the respective product portfolio.

Our approach

To meet these complex requirements, Dürr Consulting offers a structured and targeted approach to designing your assembly systems:

- Objective: The first step in our planning is to understand your specific goals and constraints. These form the basis for all further planning activities.

- Analysis: A comprehensive analysis is crucial to the design of productive assembly systems. We start with a detailed examination of your product, its structure and variance. We then analyze your assembly processes and their dependencies, as well as the available resources.

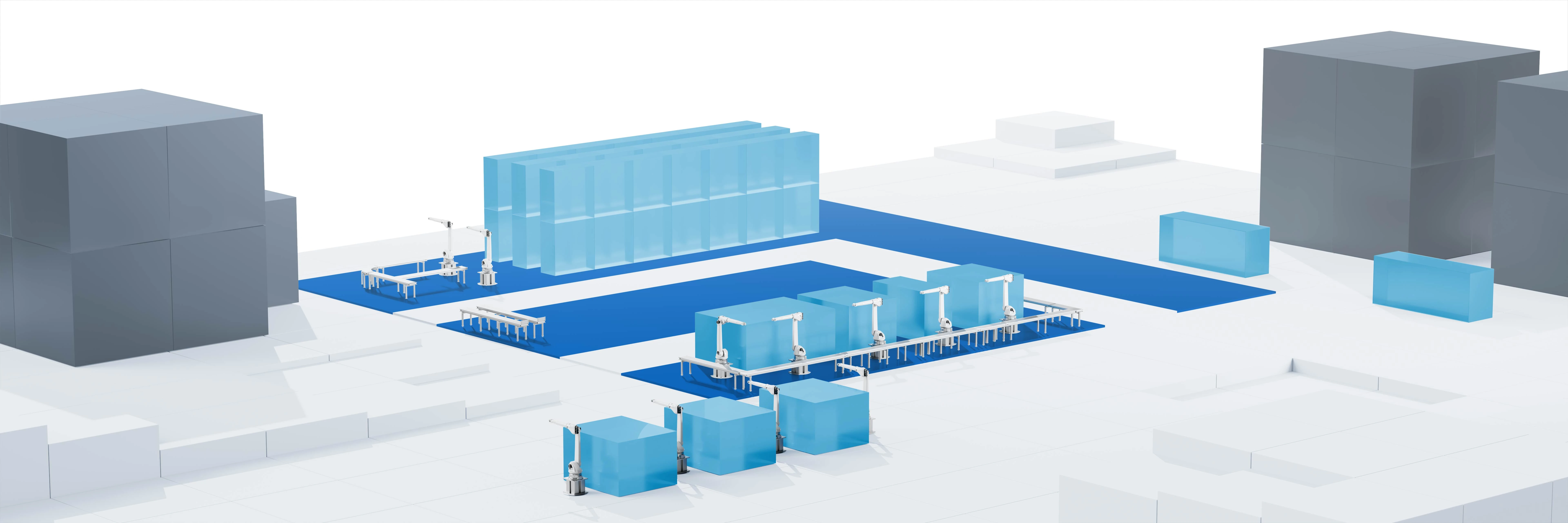

- Design: We work closely with you to develop customized assembly systems. These range from manual individual workstations to complex assembly lines and highly flexible matrix production systems. You determine the desired level of detail – from a rough concept development to the detailed design of each individual workstation.

- Implementation planning and support: We support you not only in the planning, but also in the implementation. This includes the creation of specifications, the definition of the implementation steps and support until the final realization of your assembly system.

Our strength – 40 years of operational experience

Dürr Consulting offers in-depth expertise and innovative solutions in assembly planning. We have been working in various industries for over 40 years, including mechanical and plant engineering, automotive and automotive supply, electronics manufacturing and medical technology. We use the latest digital factory planning and simulation tools to visualize and validate planning results. This combination of experience and innovation makes us a reliable partner for your company.

Your added value

Benefit from the economic and innovative design of your assembly systems – from planning to implementation. Our customized solutions strengthen your competitiveness in the long term and contribute significantly to your company's success. With our customized approach, we design productive and innovative assembly systems that are tailored to your specific objectives and initial situations. Let us shape the future of your production and sustainably consolidate your market position together.

With our approach and expertise, we support you in mastering the current challenges of production and successfully leading your company into the future.

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany