Industrialization

In order to successfully implement strategic planning in a production plant, production processes must be carefully designed and manufacturing must be commissioned smoothly. Companies are often faced with the task of expanding their production capacities while increasing efficiency in order to meet competitive requirements.

Production capacities can be expanded in existing production facilities or in a new building. Both cases require careful planning. In addition, the integration of the latest technologies should be taken into account in order to set up the production facility in a future-oriented manner. In the case of brownfields, an additional challenge is to continue ongoing production with as little disruption as possible during the conversion. Effective ramp-up management is crucial for commissioning the planned production facility in order to get new production lines up and running quickly and smoothly and accelerate the market launch of new products.

To meet these challenges, Dürr Consulting offers comprehensive consulting services in the areas of factory and assembly planning. Our experts help you develop an optimal factory layout that improves both the efficiency and flexibility of your production processes. We also provide support in the detailed planning of assembly processes to simplify and optimize production flows. Through targeted ramp-up management, we ensure that your production starts up quickly and effectively.

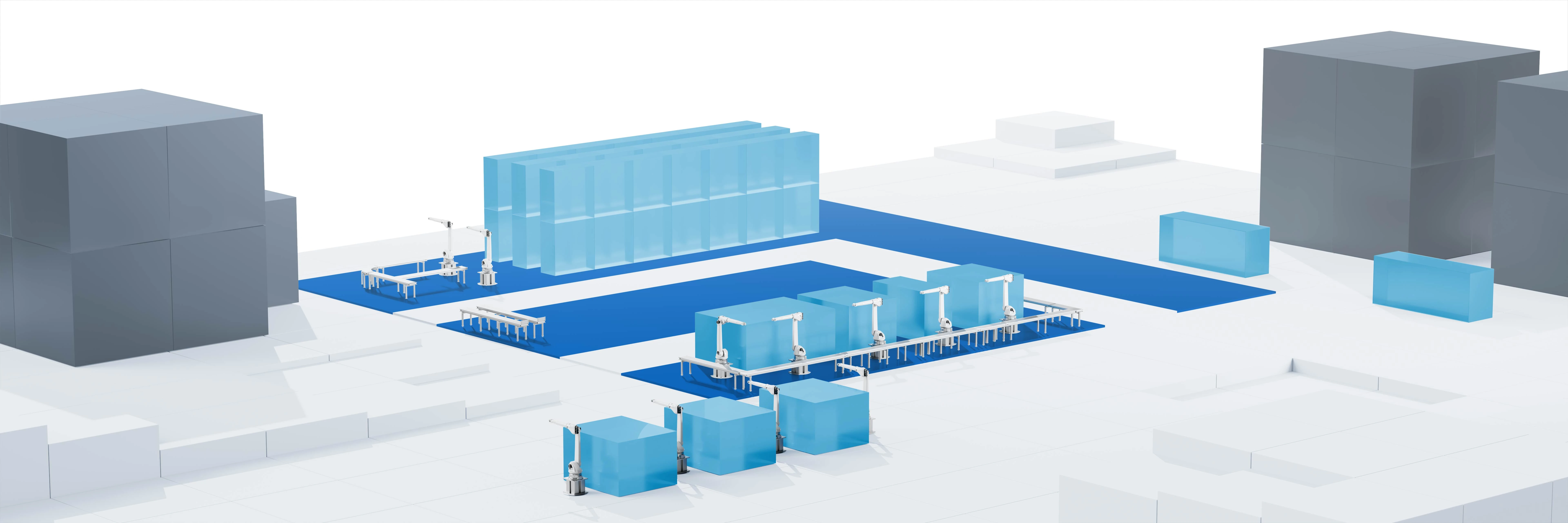

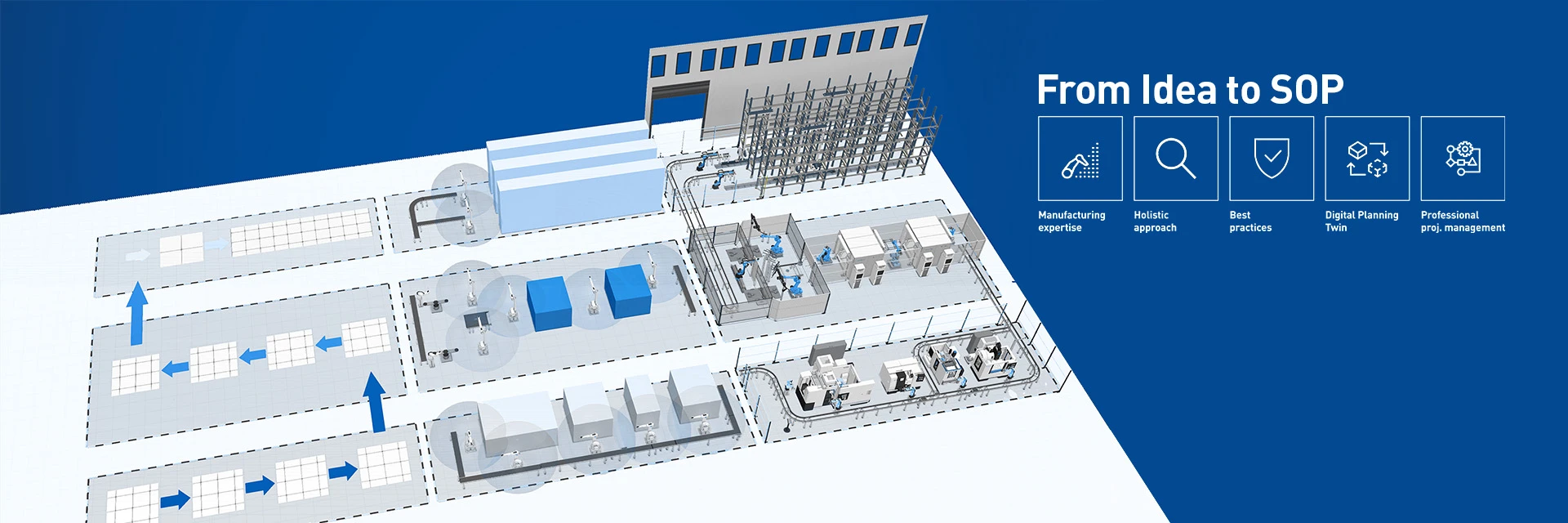

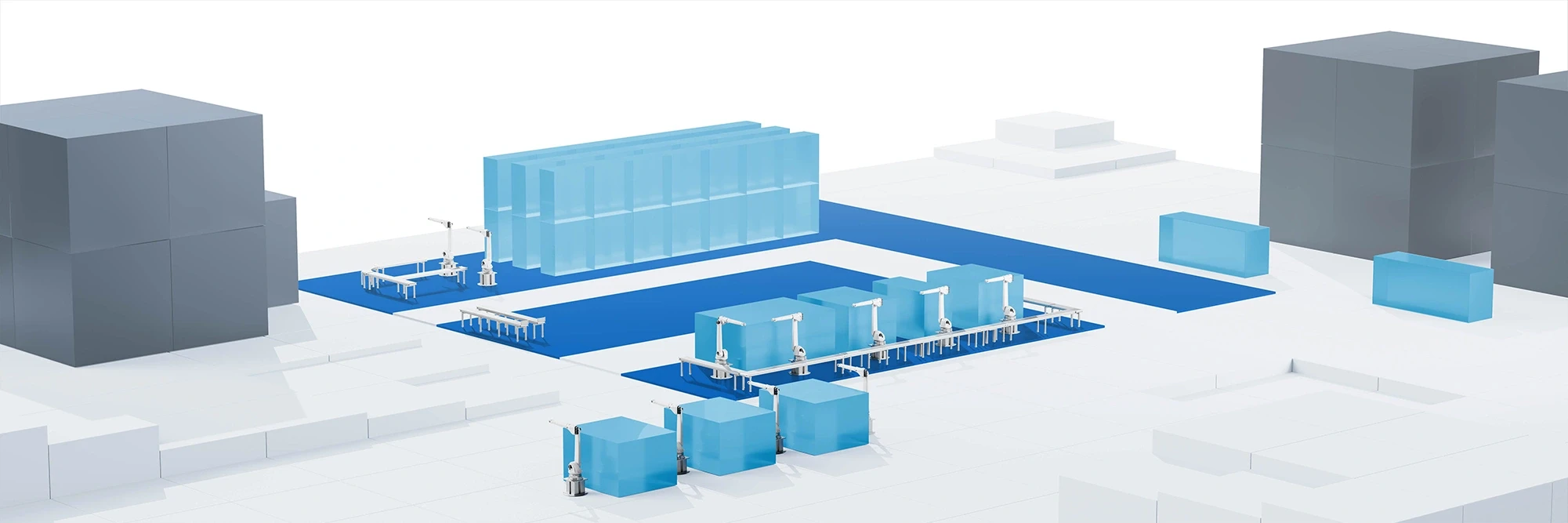

Factory planning Industry

Innovation for efficiency is the guiding principle of modern factory planning. By optimizing production processes with a thoughtful layout, intelligent material flow systems, and innovative technologies, factories are transformed into state-of-the-art, efficient production facilities. This approach boosts productivity, reduces waste, and lowers operating costs. As a result, a future-ready factory is created, significantly enhancing competitiveness. Planning is carried out virtually using 3D technology to simulate the processes before the first construction phase begins, identify errors at an early stage, and ensure the best possible planning results.

Assembly planning

Careful planning of assembly processes is crucial to ensure efficient and high-quality production. It focuses on optimizing assembly workflows, increasing productivity, minimizing errors, and reducing costs. This planning involves selecting appropriate techniques, optimizing layouts, considering ergonomic aspects, implementing automation, and managing quality.

To meet these complex requirements, Dürr Consulting offers a structured and targeted approach to designing your assembly systems:

Automotive brownfield integration

Automotive Brownfield Integration focuses on modernizing and optimizing existing production facilities and processes to adapt them to new requirements and make them future-ready. By incorporating new technologies, automation systems, and digital solutions into existing factories, productivity and flexibility are significantly enhanced. Careful planning is crucial for the smooth execution of these modernization efforts. Given the growing need for many companies to adapt existing facilities to current demands, Brownfield Integration is becoming increasingly important as a cost-effective alternative to building new factories.

At Dürr Consulting, we understand these complexities and offer customized solutions that future-proof your automotive production.

Ramp-up management

Ramp-up management is crucial for the successful launch or scaling of new production facilities. It involves all activities necessary to gradually increase production capacity and ensure a smooth start and transition to full production. Professional planning and management of the ramp-up process minimizes risks, controls costs, and reduces lead times. Our strategies for capacity expansion enable you to increase production capacities without significant interruptions, so that you can react flexibly to increasing demand. Our consulting approach to ramp-up management is based on a comprehensive analysis of your specific challenges, in order to then implement a customized ramp-up management solution for you.