Case Studies

Latest insights, innovations and perspectives from Dürr Consulting. In times of open knowledge exchange, discover current content from our projects and trends that engage and change society and our business environment. Together we shape the future.

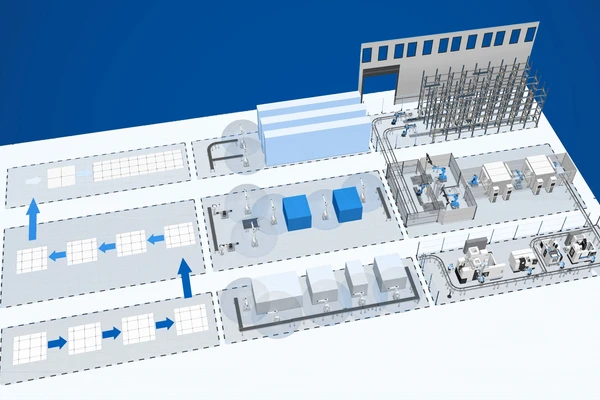

Dürr Consulting was commissioned with the holistic planning of a scalable and highly automated factory for an innovative product in the "New Energy" sector. As the customer had only little prior experience with automated systems, the target automation level of over 95% posed a particular challenge. The process steps and procedures for manufacturing the product had already been defined and tested in prototype production. The industrialization of these processes was necessary for the future increase in quantities, whereby the process maturity and series production capability still had to be proven for some processes.

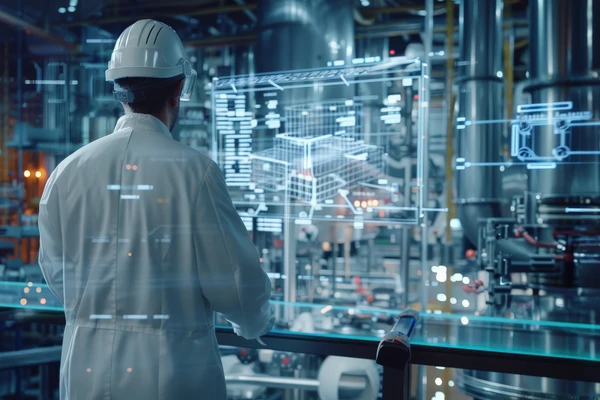

A Manufacturing Execution System (MES) supports manufacturing companies to increase planning accuracy, process and product quality, equipment uptime and overall process transparency. Furthermore, acting as the central hub for manufacturing data, the MES is the basis for the Smart Factory. The automotive industry, in particular, has relied on IT-supported production control and supervision for years. This trend is increasingly followed by other industries as this case study of an agricultural machinery manufacturer shows. As part of a master-planning project, the company has asked Dürr Consulting to develop a MES concept tailored to the specific customer’s situation and vision.

In a recent interview an automotive expert affirms: “If someone asks for lean vs. smart, I’ll tell him that we definitely need a combination of both.” Not only in the automotive industry, but in all industries, a lean, smart and flexible production is the key to success in today’s fast-moving and demanding market. In this context, Dürr Consulting was asked by a world-leading manufacturer of hydraulic motors to develop the vision and concept of a future-ready, flexible and adaptable assembly line in 4 months only.

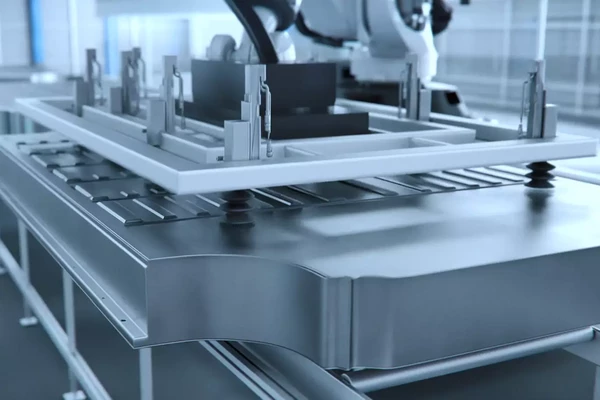

Starting with an almost blank slate and ending with a run up to full capacity battery pack assembly in the specified time and quality, that was the job of Dürr Consulting in consultancy and planning support for a premium car manufacturer. This was one of the main challenges along with the definition of new standards which are matched to the existing production system and the low product maturity due to late product development. This case study demonstrates that an excellent methodical and systematic approach develops a state-of-the-art battery assembly that meets the customer requirements in quality, time and cost.

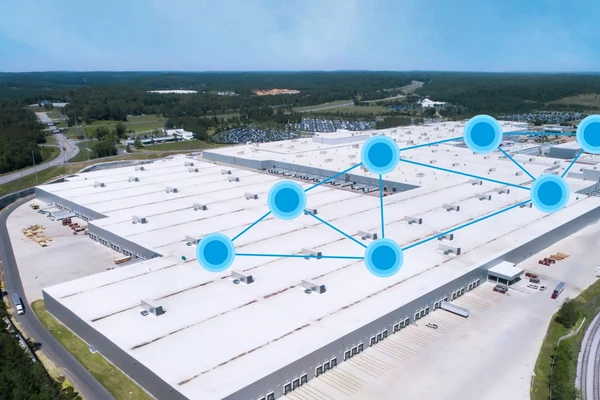

Dürr Consulting advised Vaillant on the planning and construction of its new heat pump plant in Senica, Slovakia, successfully completing an important project. “Heat Pump World Senica” manufactures heat pumps in accordance with the highest international standards. In line with its “From Idea to SOP” guideline, Dürr Consulting supported the entire process—from the planning phase to the start of production. The project benefited greatly from Dürr Consulting's expertise and many years of experience in factory planning.

Development project managers (DPMs) encounter a wide variety of daily challenges, from scheduling releases and time lines in close collaboration with the customer and reporting regularly to the Steering Committee, to dailies with the development team and technical discussions with the solution architect – and not forgetting comprehensive coordination with the general project manager.