Virtual factory planning

How virtual planning ensures accuracy, quality, and efficiency throughout the entire planning process

When planning a highly complex production process, for example due to a high degree of automation and a large number of variants, numerous requirements must be taken into account and changes must be responded to dynamically. Conventional planning models are often unable to adequately map these challenges. This often makes efficient collaboration between clients and planners more difficult. Virtual factory planning – i.e. end-to-end planning and simulation in a virtual environment – not only simplifies communication with various stakeholders, but also enables a much more precise and dynamic representation of the planning or production environment. This approach enables the early validation of concepts and ensures the functionality of the planning with regard to the KPIs to be achieved. These advantages mean that planning in a virtual environment is increasingly becoming the gold standard.

Motivation, starting point and challenge

The customer commissioned Dürr Consulting with the holistic planning of a scalable and highly automated factory for a new product in the "New Energy" sector. As the customer had only little prior experience with automated systems, the target automation level of over 95% posed a particular challenge. The process steps and procedures for manufacturing the product had already been defined and tested in prototype production. The industrialization of these processes was necessary for the future increase in quantities, whereby the process maturity and series production capability still had to be proven for some processes.

Step 1: Basic planning

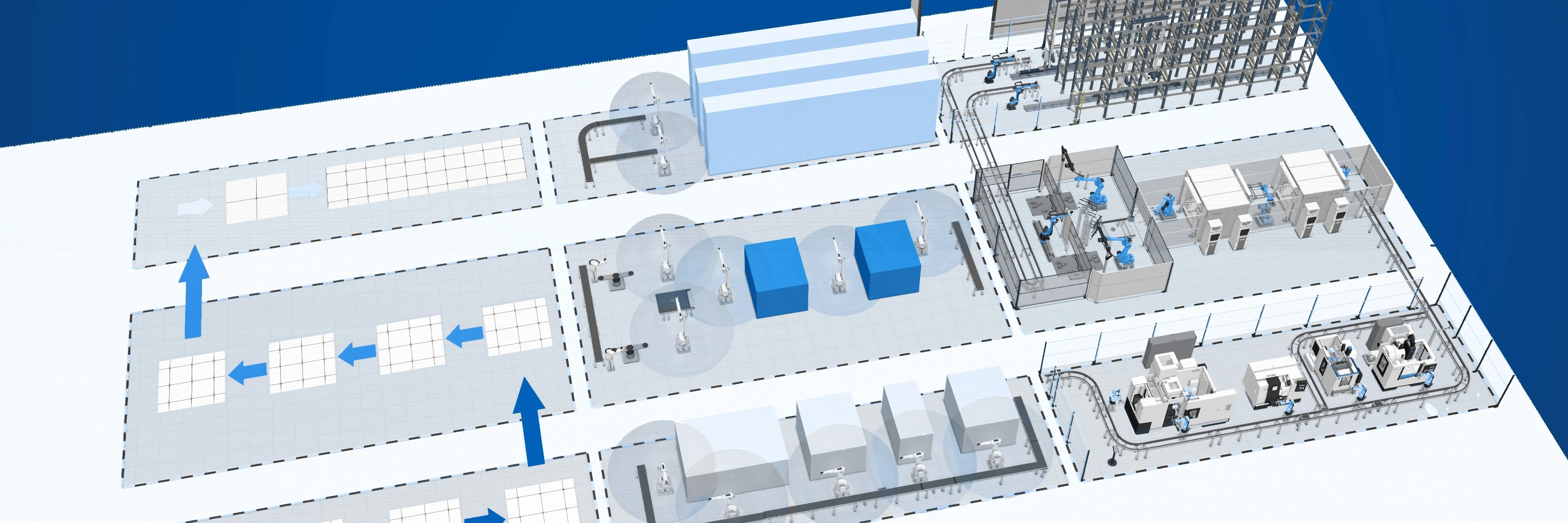

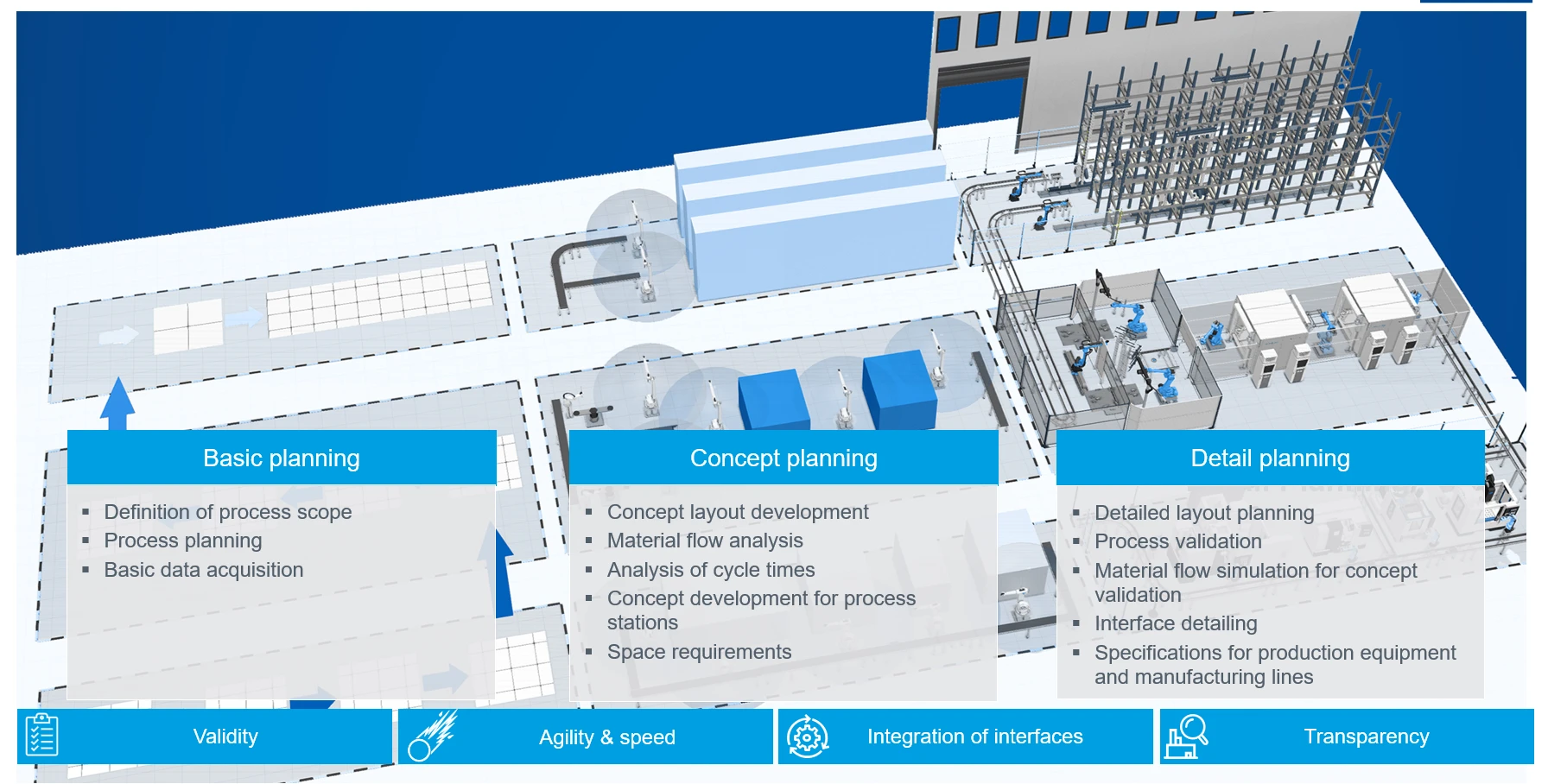

In the basic planning phase of the project, the project objectives are defined and all planning principles and requirements are compiled in the project brief. This takes into account quantities, ramp-up scenarios, key performance indicators (KPIs) and technical requirements. The project brief creates the basis for targeted planning and documents all premises and restrictions. The production and assembly processes are then defined and divided into stations. The process sequence is mapped in the virtual planning environment with a rough area indication (see Figure 1, below).

Concept planning

In the second project phase, concepts are developed for the individual process stations. Based on the requirements for the stations, the process equipment and possible solutions for the handling and conveyor technology are selected. The concept development is carried out throughout in the virtual planning environment, in which the selected equipment is visualized and layout variants are created for each station. For further evaluation of the variants, the space requirements of the stations are evaluated and compared. The concepts are also analyzed with regard to reachability, accessibility and workspaces.

For complex process stations, cycle time evaluations are carried out using basic process simulations and the concepts are thus simulatively validated. This makes it possible, for example, to check at an early stage how many handling robots are needed in a station to achieve the required cycle times. The solution variants and technologies developed are evaluated on the basis of criteria agreed with the customer and a selection is made for each station.

Based on this data, a virtual 3D layout of the entire system is created, in which all line structures and a grid dimen- sion are defined, the connecting conveyor systems are planned and the interfaces between the modules are de- tailed. The 3D layout is then integrated into a model of the existing hall in order to check the interfaces to the build- ing. The CapEx and OpEx cost indication is determined on the basis of the system concept.

Detailed planning

The final planning step involves detailing the system concepts and an in-depth analysis of the equipment, interlinking and interfaces. This provides the basis for an overview of critical stations and processes that need to be further optimized. The digital twin of the system from the concept planning phase is further detailed based on these findings. A detailed 3D material flow simulation is carried out using the digital twin in order to validate the refined planning status. This includes an abstract representation of the processes as well as a complete mapping of the workflows, including handling and positioning processes.

Goals

The aim of the project was to develop an automated, scalable and digitalized production concept that would optimally meet the customer’s requirements. In addition to system planning, the areas of logistics, quality and technical building equipment (TGA) were also to be taken into account for the holistic planning of the future factory. As part of the planning, critical areas of activity were to be identified and secured both in processes and systems as well as with regard to the associated schedules.

The result should be a concept that can be awarded to the customer.

Approach

In order to best meet the high technical requirements for future production, a structured planning approach with the following three standardized steps was used: Basic planning, concept planning and detailed planning (see Figure 1). Due to the complexity and the low level of maturity of the processes, the early and ongoing validation of concepts, the coordination of interfaces and thus the minimization of risks were also aimed for. Virtual planning based on a digital planning twin was therefore established throughout all planning phases.

The digital twin acted as a “single source of truth” in which the current planning status was mapped and validated. The integration of the system into an existing or greenfield hall was also planned. In parallel, the logistics and quality concepts, the technical building services, the control technology and production IT were planned. The focus of this case study is on the methodology, results and benefits of virtual planning.

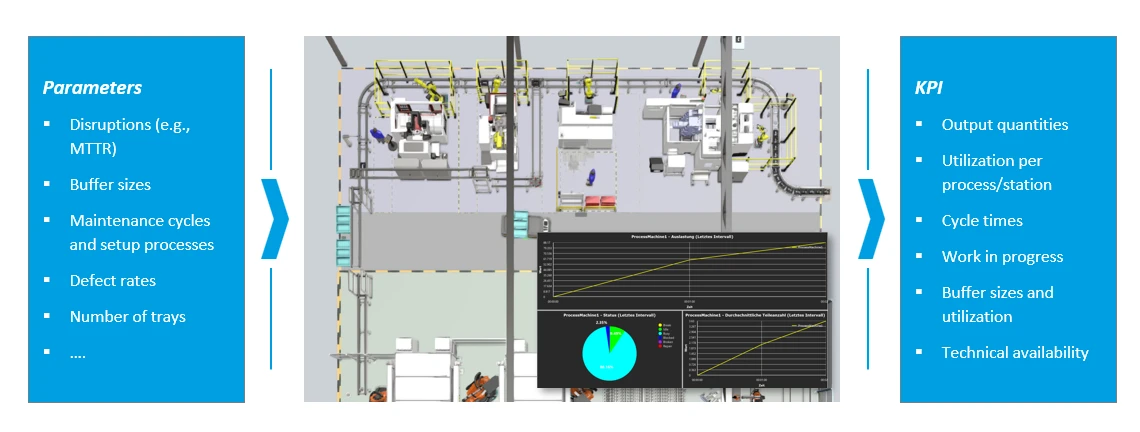

The realistic production simulation forms the basis for the subsequent calculations of:

- Output quantities

- Utilization per station

- Cycle times

- Buffer sizes

- Technical machine availability

Three scenarios (best, mid and worst case) are defined for the simulation, which differ in terms of the availability of the modules and robots, the consideration of NiO parts, the SPC checks, the maintenance cycles and the set-up processes. The KPIs for the evaluation are coordinated and implemented according to the objectives (see Figure 2).

By simulating and evaluating the three scenarios, the performance of the system and the effects of disruptions can be analyzed. Bottlenecks can be identified and optimizations can be derived. To illustrate this, a generic scenario is presented: This station comprises several parallel machines that are loaded with two robots on a seventh axis. The evaluation of the simulation showed that the insufficient output quantity of one station is due to the high proportion of travel times of the robot. By optimizing the arrangement of the components, it was possible to adjust the cycle time of the station so that it corresponds to the targeted size. In addition, the evaluations allow cycle time estimates to be confirmed and interfaces and their transfer to connecting conveyor systems to be optimized.

Optimizations for system planning are derived on the basis of the material flow simulation and implemented in the virtual environment. The CapEx and OpEx estimates developed in the concept planning phase are also updated on the basis of the new findings and adjustments.

Benefits from the customer's perspective

- Detailed system concept ready for implementation

- Thanks to end-to-end planning and simulation in 3D, system concepts and solution variants can be validated at an early stage. In particular, the interfaces between the individual plant modules can be coordinated and specified in the tender documents. In parallel to plant planning, logistics, quality assurance, building services planning and the end-to-end digitalization of the future factory are also considered as part of integrated factory planning.

- Technical feasibility and reliable budget indication

- Feedback from potential suppliers on technical feasibility and prices is recorded as part of an RFI process and incorporated into the planning.

- VR walkthrough with project partners and decision-makers on the customer side:

- The virtual layout simplifies communication and collaboration with the customer. For example, we use VR glasses to give our customers a tour of the plant with a realistic insight into the simulated production.

- Identification of critical process stations and bottlenecks:

- Using the 3D material flow simulation, bottlenecks in the system could be systematically identified and the necessary optimizations derived. For example, by integrating small intermediate buffers in the assembly line, the availability of the entire system could be significantly increased. The findings were transferred to the system specifications for the RFQ process.

Conclusion

This project focused on the industrialization of an existing pilot line to large-scale production. The overriding requirements for the project included a degree of automation of over 95%, a high technical availability of 95% and short cycle times of less than 4 seconds. In order to meet these requirements, a corresponding system and factory concept was systematically developed.

The established procedure with the three steps of basic, concept and detailed planning ensured that all relevant aspects were taken into account and innovative solutions were found. In particular, end-to-end virtual planning and simulation with the derivation of relevant KPIs proved to be decisive in mastering the high level of complexity and continuously safeguarding the planning. This enabled the early harmonization of interfaces and the identifica- tion and optimization of risks and bottlenecks in the plant concept.