Digitalization strategies & Digital Readiness Assessment

Digital transformation has evolved from an academic discussion to reality in the manufacturing industry. Essential for the development of a roadmap to define and prioritize digitalization initiatives is to answer the questions: "Where do we stand as a company today?" and "Where do we want to go?". Dürr Consulting offers the Digital Readiness Assessment to provide a structured approach to answer those questions and, based on an industry benchmark, to derive specific recommendations for actions.

> Download - Digital Readiness Assessment White paper

> Download - Holistic production IT planning for a greenfield automotive plant case study

Industry 4.0 - The digitalization of the manufacturing industry

The fourth industrial revolution has reached the heart of the manufacturing industry. After mechanization and electrification, from the 1970s onwards, automation led to disruptive changes in production, it is today the digitalization that is enabling companies to achieve significant productivity gains.

While the topics surrounding Industry 4.0 and IIoT were discussed primarily in the research environment for a long time, it is now evident to the vast majority of operations managers that no company can escape the current technological leap in the long term. The ever-increasing demands on productivity, quality and flexibility require production managers to permanently improve processes using new digital solutions. Stagnation is regression is in the age of Industry 4.0 more valid then even before.

Using scarce resources efficiently - The target picture sets the basis for the digitalization roadmap

The systematic implementation of digital solutions - starting from simple dashboards to machine specific applications, such as digital quality assurance and smart maintenance, to comprehensive manufacturing execution systems (MES systems) - is an effortful and often tedious process. The high effort is almost always contrasted by limited personal and financial resources - a clear prioritization of the planned digitalization activities is therefore essential. This in turn requires an aligned target picture of the digitalized production. Only a well-defined roadmap with timetables and responsibilities allows for a structured tracking of digitalization initiatives. Hence, the two central questions for the development of a digitalization roadmap are "where are we today" and "where do we want to go".

Digital Readiness Assessment – Evaluate your digital maturity level

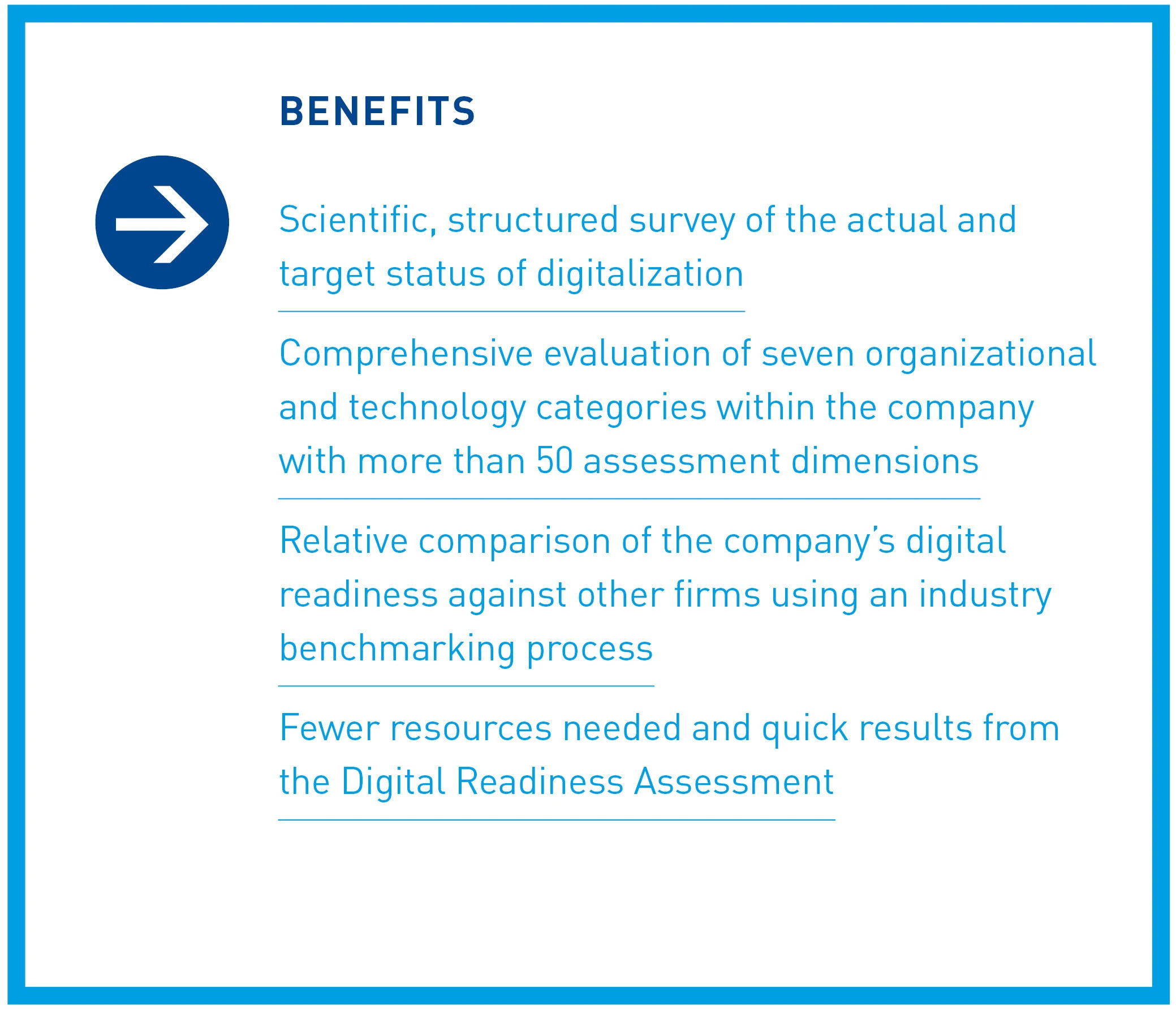

To determine the status quo as a critical starting point for the development of a digitalization roadmap, our team developed, in cooperation with the Institute for Production Technology at the University of Karlsruhe, a science-based and yet practicable assessment methodology of the digital maturity level.

Within the framework of the assessment, a total of seven categories with more than 50 assessment dimensions are covered in the four main categories of organization, technology, production, product & business model. This allows for a comprehensive assessment of the current digital maturity of the company.

Enabler

Performer

Organization

Strategy and structures

- Holistic 14.0 strategy/vision

- Strategy implementation

- Organizational anchoring

- Agile structures

- Investments

- Network collaboration

- Strategic partnership

Employees and culture

- Qualifications

- Training

- Social collaboration

- Willingness to change

- Shaping change

- Decision-making authority

Technology

Data acquisition

Recording by object, time and content of:

- Customer order data

- Workpiece data

- Material data

- Tools and utilities

- Means of transport

- Quality data

Connectivity and information systems

- Digitalization of processes

- System architecture

- Data storage

- Interfaces

- Data governance

- Data protection

- IT security

- Resilience of IT infrastructure

Production

Data-driven decision-making

- Research/ development

- Outline planning

- Detailed planning/ control

- Intralogistics

- Interlogistics

- Mantenance

- Quality assurance

Intelligent process management

- Warehouse

- Material flow

- Setup/production planning

- Production

- Maintenance

- Quality assurance

Business Model

Expansion of the service portfolio

- Intelligent products

- Sharing information in the use phase

- Feedback from the use phase

- Customer individualization/ integration

- Data-driven services

- New business models

From the target picture via the gap analysis to the roadmap

After recording the status quo, we develop a target image of digitalized production together with your responsible production or plant manager. The target picture is also defined along the seven assessment categories. The fields of action are then derived from the gap analysis of the target image with the status quo. Based on our extensive experience as operations consultants as well as a global technology leader in the field of mechanical and plant engineering, we support the definition of necessary actions in order to successively reduce the identified gap. In the next step, these actions are prioritized according to the assessment results and linked to a defined timeline. With the identified starting point, the formulated target picture and the defined roadmap, the challenge of the digital transformation can be addressed in a structured way.

Industry benchmark for comparative assessment of the own digital maturity level

A key feature of the Digital Readiness Assessment is the assessment of your company compared to an industry benchmark sample. On the one hand, this is done quantitatively by comparing the mean values and the values of the best companies in the benchmarking sample and, on the other hand, through our consulting experience. Specific results of individual companies are never disclosed to third parties.

Digital Readiness Assessment for small and medium-sized enterprises

During the conceptualization of the assessment, we made sure to keep the internal efforts as well as the costs for our clients to a minimum. On average, the kick-off, the assessment of the current situation and the definition of the target picture only requires the availability of our assessment partners for one to two days. All further activities are performed by our consultants. After a few weeks, our clients can already welcome the final report with all assessment results.

We are looking forward to getting in touch with you in order to initiate the Digital Readiness Assessment together as starting point for your digital transformation.

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany