Strategy

The right strategy for ensuring long-term competitiveness in factory and production planning

The Path from A to the Goal: Factories and their production systems form the backbone of manufacturing companies. The definition of clear strategies and frameworks is therefore crucial to successfully operate and act purposefully in dynamic and unpredictable markets. Derived from the corporate strategy, which is particularly influenced by market conditions, sub-strategies emerge for products, processes, technologies, digitalization, logistics, and other areas of production that can be evaluated based on concrete pragmatic goals.

Even in the early phases of developing new factories, well-thought-out goals provide the necessary framework to make informed decisions that determine the direction and priorities of a project. A clear strategic orientation also creates a mutual understanding of goals and methods among all parties involved, contributing to effective collaboration and smooth project execution. Pragmatically speaking, jointly defined KPIs, for instance, allow for rapid evaluation of solutions.

In the ongoing operation of factories and production systems, clear strategies and their regular review are essential to maintain long-term competitiveness and to adapt to changing market conditions or technological innovations. We accompany our clients in responding flexibly to evolving requirements and technological developments without compromising the efficiency or quality of their production. Clear strategic derivations support the sustainable optimization of production processes and foster continuous improvement.

Market Analysis

Through in-depth analyses, we help clients identify market trends and drivers and derive strategic conclusions. Our approach aims to optimally align products and services with market needs. We assist you in developing a clear strategy for market entry, investment and location decisions, sales strategies, and development projects, relying on continuous fact-checking.

Production strategies

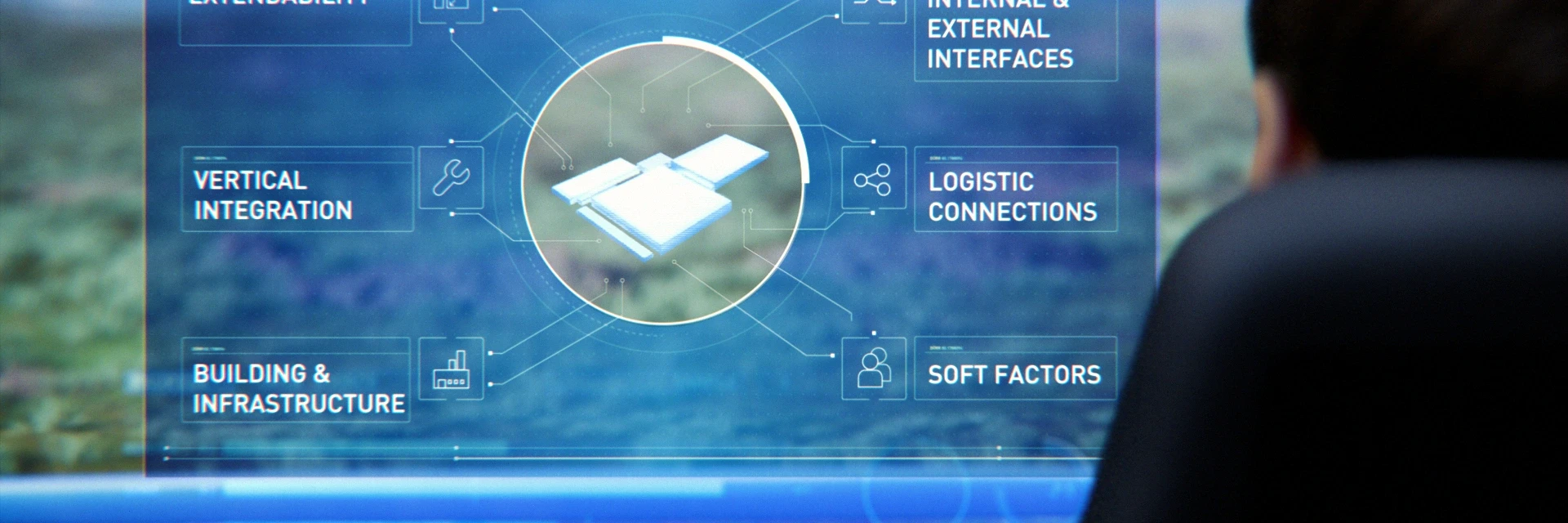

In close collaboration with our clients, we define the orientation of your production. Based on our established approach, we develop a clear vision derived from the status quo. Transparency and traceability of decisions for all stakeholders are important to us, creating high acceptance for implementing new production strategies. Besides analysis and strategic derivation, we also support you in implementing the new strategy with comprehensive PMO services and technical consulting. From the idea to SOP, we support you in site selection and master planning. For existing plants, we define concrete action scopes based on a well-thought-out and tested flexibility & adaptability assessment to make them fit for the future. For new production sites, we assist in site selection and master planning, which we have conducted for numerous renowned clients worldwide. Utilize our knowledge and experience to design your production efficiently and future-proof.

Production network strategies

In a globalized world, various relationships exist at the information flow and material flow level between production sites, suppliers, and customers, which are subject to constant change. External challenges such as geopolitical risks, trade barriers, and supply chain disruptions must be consistently analyzed, and the production network adapted to them to maintain competitiveness and delivery capability. As part of a globally operating plant manufacturer, we are particularly aware of these challenges. Therefore, we have developed structured methods to support our clients from network analysis to adaptation and redesign.

Smart Factory & Digital Readiness Assessments

Digital transformation has evolved from an academic discussion to reality in the manufacturing industry. Essential for the development of a roadmap to define and prioritize digitalization initiatives is to answer the questions: "Where do we stand as a company today?" and "Where do we want to go?". Dürr Consulting offers the Digital Readiness Assessment to provide a structured approach to answer those questions and, based on an industry benchmark, to derive specific recommendations for actions.

Find out how the Digital Readiness Assessment will support you in developing your company specific digitalization roadmap.

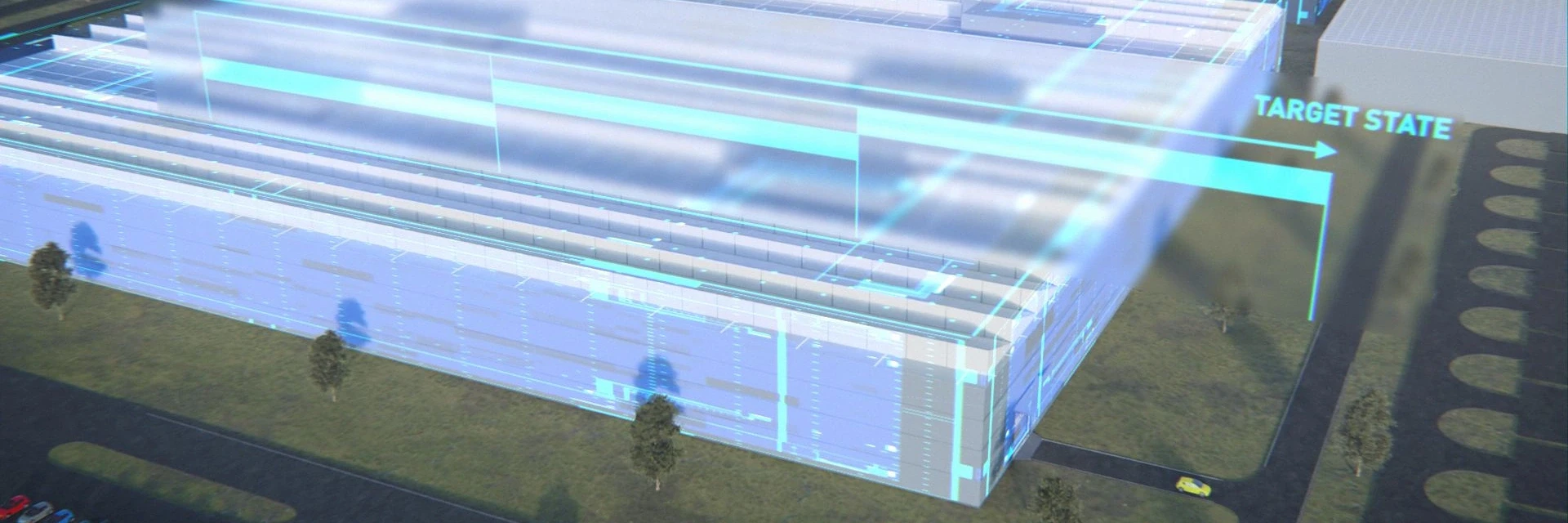

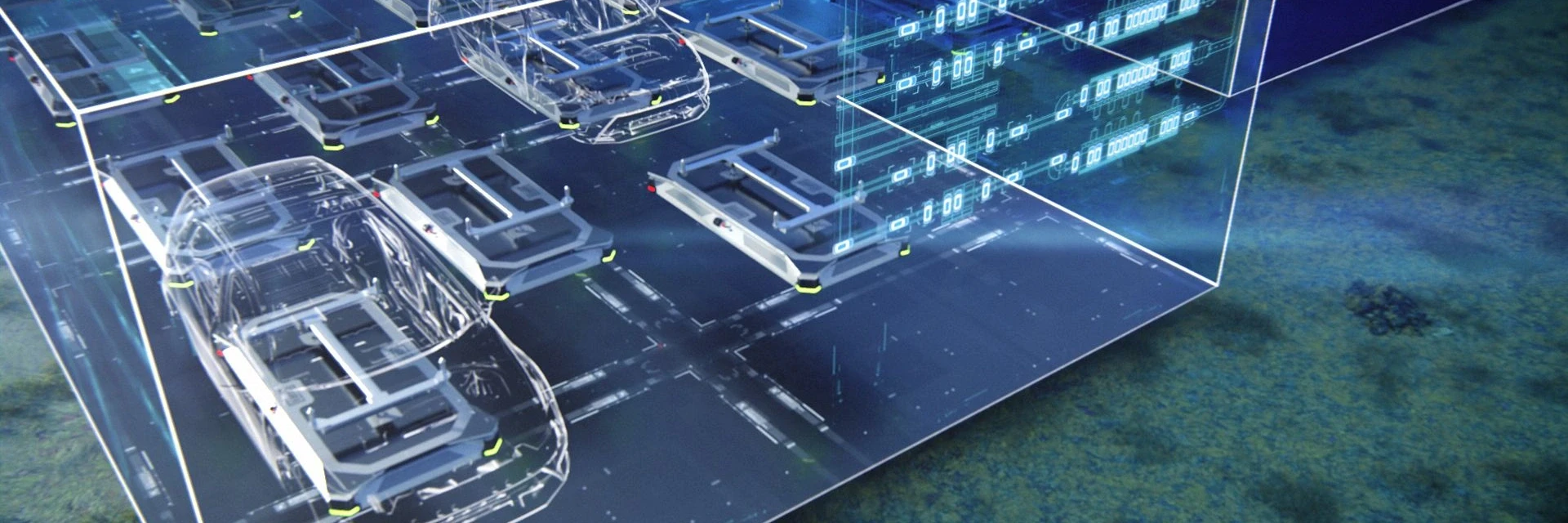

In addition to established methods, for example lean management, the digitalization of production is meanwhile vital to continuously improve quality and productivity of the production system. Hence, the target state is the smart factory, which offers maximum transparency and flexibility.

On the journey to the smart factory, we support our customers with various planning services along the entire ISA-95 automation pyramid. Our services range from equipment and layout planning, over the development of a coherent control concept, up to the planning and design of comprehensive production control systems on the MES and SCADA level.