Virtual factory planning – Plan digitally. Implement efficiently

How virtual planning and simulation ensure validity, quality, and efficiency throughout the entire planning process

For over 40 years, we have supported our customers in factory planning – with a clear commitment: to identify technological developments early and to continuously evolve our methods and tools.

The challenges of modern production environments are diverse, making the complexity of factory planning projects extremely high. For example, the following trends in industrial production must already be considered in the early planning phase:

- High level of automation

- Integration of AGV systems

- Large product variety and complex processes

- Volume fluctuations and scalability requirements

Our answer: The digital planning twin.

With state-of-the-art 3D planning and simulation tools such as Visual Components, Vistable, Plant Simulation, selected add-ons, and an interface to NVIDIA Omniverse, we create a seamless digital planning environment for the collaborative creation, editing, and presentation of the digital twin of your planned factory or facility.

Our approach in planning projects

Virtual planning with Dürr Consulting – experience speed, precision, and reliability at every planning stage

Ensuring validity, quality & efficiency throughout the entire planning process

All three phases of the factory planning process are realized in an virtual environment:

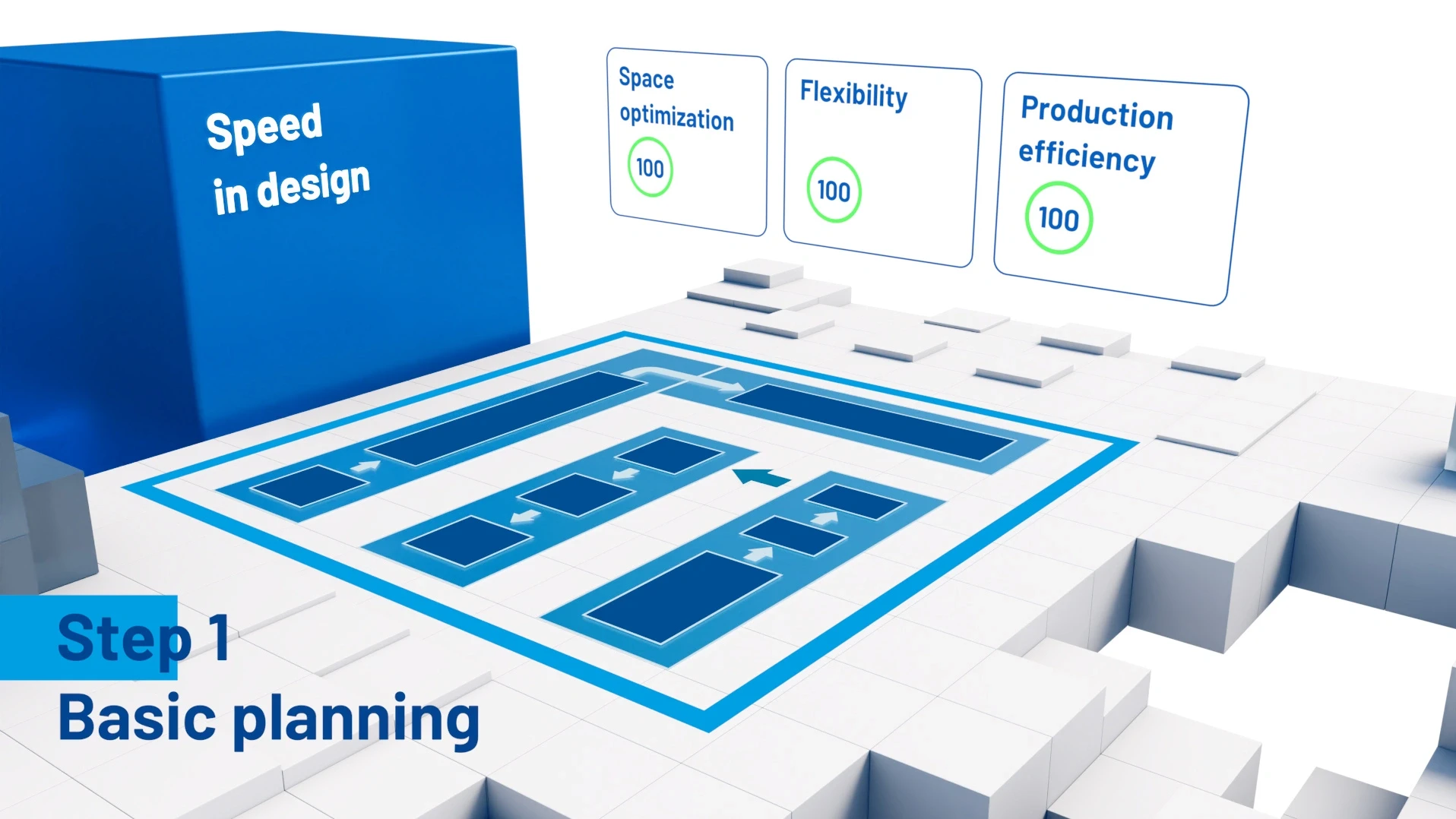

1. Basic planning

First, we define the project scope and objectives together with you and establish an initial process plan.

Quantities, ramp-up scenarios, key performance indicators (KPIs), and technical requirements are taken into account, and all assumptions and restrictions are documented.

Manufacturing and assembly processes are defined and divided into stations.

Finally, the process sequence is mapped in the virtual planning environment with a rough area indication.

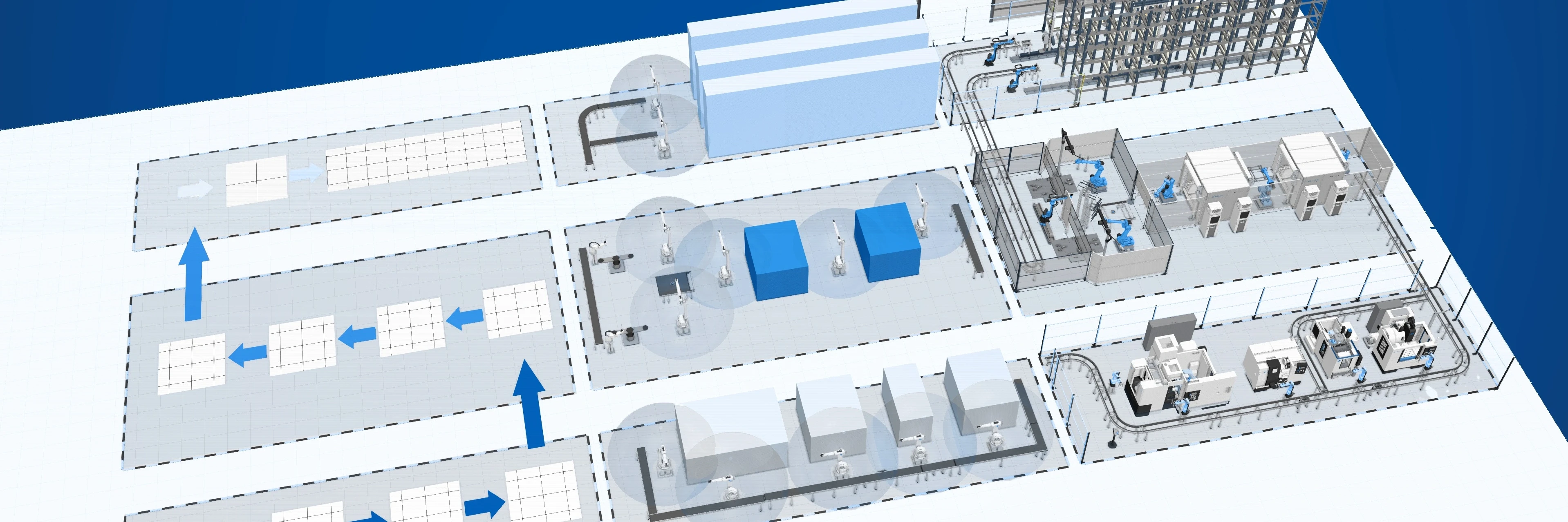

2. Concept planning

In the second step, we jointly develop the framework concept with a rough virtual 3D layout of your factory.

Material flow and cycle times are analyzed, and space requirements are determined.

Concepts for individual process stations are developed, process equipment is selected, and interfaces and potential solutions for handling and conveyor technology are considered.

The concept development is carried out entirely in the virtual planning environment, where the selected equipment is visualized and layout variants for each station are created.

Accessibility, reachability, and workspaces are analyzed and validated through process simulations.

Based on the equipment concept, CapEx and OpEx cost indications are determined.

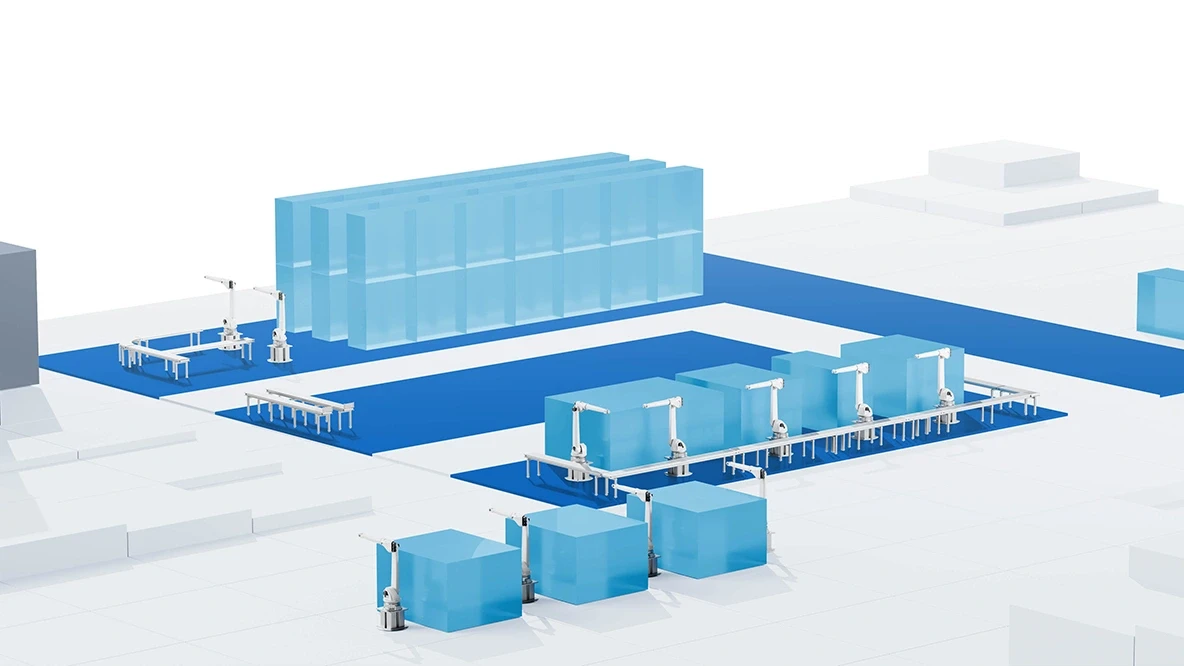

3. Detailed planning

The focus is on detailed layout planning with process simulation and validation.

The Digital Planning Twin of the system is further refined based on insights from the concept planning phase.

At this stage, detailed 3D material flow simulations are conducted, including abstract process representations and complete mapping of operations such as handling and positioning.

Weak points and sources of error from previous planning steps (e.g., at interfaces) can be easily identified and directly eliminated.

Benefits of virtual planning in 3D

Speed in design

- Drag-and-drop from extensive libraries for robots, equipment, and conveyor systems

- Direct import of layout data from AutoCAD, SolidWorks, Siemens NX, and more

Fast decision-making

- Intuitive visualization of layouts, processes, and workflows in 3D enables stakeholders to understand, evaluate, and make decisions quickly

Accuracy and Reliability

- True-to-scale representation: 3D models are based on precise CAD data, ensuring exact dimensions, distances, and space requirement

- Collision checks: Automated checks detect conflicts between machines, building structures, or media routing early

- Data consistency: Changes in the model directly affect all dependent elements – fewer errors due to manual transfers

The option to validate various planning parameters using simulation further enhances the reliability of planning results.

Expansion of the virtual planning model

By extending the virtually planned factory model with behavioral logic, simulations and further analyses can be conducted within the same software based on the existing planning.

Process simulation and material flow analysis

The combination of 3D planning and simulation provides a reliable basis for investments while simultaneously reducing the effort for everyone involved.

Benefits:

- Simulation of production processes, cycle times, bottlenecks, and lead times

- Visualization of material flows, buffers, and transport routes

- Identification and elimination of inefficiencies

- Scenario comparison for informed decision support

- Evaluation of KPIs such as utilization, energy consumption, and throughput

After planning comes commissioning

Another advantage of digital planning is the possibility to support virtual commissioning:

- Testing control logic (e.g., PLC programs) directly in the 3D model

- Early detection of errors before real implementation

- Integration of existing virtual commissioning models for realistic simulation

- Avoidance of duplicate parameterization work

This results in shorter commissioning times and lower costs.

Software selection | Reduce complexity – with the right solution

The wide range of tools for 3D planning, simulation, and virtual commissioning presents major challenges for companies. Often, there are multiple solutions for seemingly identical use cases—with different strengths and weaknesses.

Dürr Consulting supports you in selecting the right software solution based on:

- Functional requirements of key use cases (e.g., logistics planning, evaluation simulations)

- Non-functional requirements (e.g., interoperability, licensing models)

- Experience from the Dürr Group and direct exchange with end users

Our approach:

In five steps, we develop a well-founded recommendation for the right solution that meets your requirements while also reducing the complexity of your software landscape.

- Overview of current solutions on the market

- Creation of a longlist (up to 10 products)

- Shortlist based on use case suitability (3 products)

- Detailed evaluation of the shortlist using weighted criteria

- If necessary: Joint prioritization/reduction of requirements to minimize the number of required tools

Do you have questions about virtual planning, simulation, or virtual commissioning, or about selecting the right software? We look forward to hearing from you and discussing your specific requirements.

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany